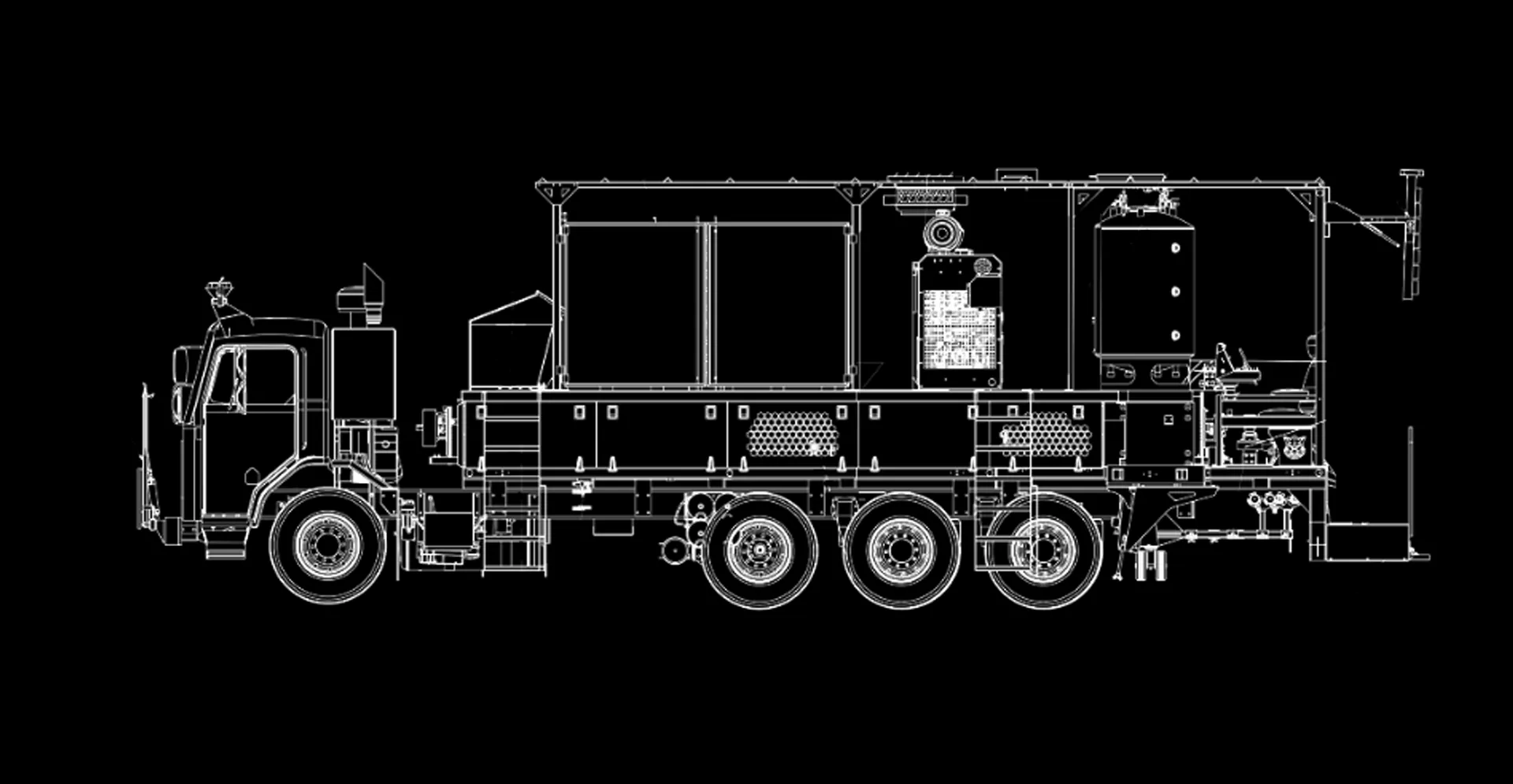

Lateral Kettles provide for:

A.) Material loads at your feet, not 12’ in the air.

B.) Low center of gravity for even weight distribution.

C.) Unlike vertical melters, horizontal mixers lift & smear cold material vertically over the walls of the kettle thereby melting material quickly even when kettles are empty.

D.) Kettles extend all the way to the rear of the truck eliminating much of the plumbing formerly associated with thermoplastic trucks. There is no plumbing between the Kettle & prescreen, knife valve, Hog Pump, final filter & gun hoses.

E.) Our helical mixer design forces material to smash & mix rather than allowing it to travel in circles in a solid clump for hours.

Just two hot oil pumps.

The Thermo Hog uses only 2 kettles, NOT 4-kettle configurations offered by competitors.

Kettles can be continuously fed up to 10,000 lbs. of material per hour without a decrease in temperature.

Laterally-stowed kettles allow for exceptional weatherproof insulation.

One hour start-up time from one day to the next.

Very low “cold core diameter”: 11 inches max VS 36” or more on competitive designs. This radically improves cold start-up times after a long weekend.

Hog speed control automates speed with no modifications to the truck's driveline.

Hog Pumps vs Roper pumps. Much easier & less costly to rebuild. Our pumps do not force glass against gears which will crush the beads. Instead, our Hog Pumps have ample clearance for beads to pass.

Spray, extrude & profile guns are available.

Pointer bar, laser, and or Camera with crosshair generator.

The Thermo Hog TH12 is revolutionizing the pavement marking industry. Through its innovations, stripers are saving time and money while increasing quality and performance!

Get the Thermo Hog TH12 specification sheet that you can print and save to your computer for review at any time. A great tool for model comparisons and for comparing the Thermo Hog TH12 to other manufacturer's equipment. Specification sheets contain: