Lateral tanks under the deck

- Eliminates partial totes of material and resulting waste

- Selective material storage on deck (bring the color or beads you need.)

- Huge increase in material capacity within work zones

- Instantaneous loading of additional material without the use of forklifts and large staging area

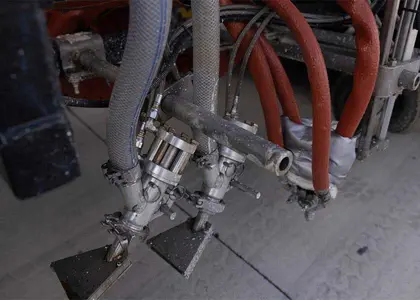

Inline pump configuration VS triangle or 5 plex designs

- Allows for super easy access to each pump leg to change or fix packings etc.

Canopy above material deck

- Protection from the elements

- Provides a place for hanging glycol heaters which allows you to heat next load while you stripe out your current load.

One burner vs 3-4

- Far fewer wires and associated controls and amperage draw

One glycol pump vs 4-6

- Far less clutter, plumbing, and associated maintenance

Granco Pumps that pressure feed high-pressure pumps

- 360° of access to high-pressure pumps at waist level

- High-pressure pumps not used for heating. High pressure pumps on other trucks used to recirculate material for heating 70% of the time.

Instant low pressure high volume material recirculation system

- Recirculation at low pressure results in expanded pump life

- No glycol-jacketed lines

- No high pressure nozzle in your recirc lines

- Excellent gun visibility

- No cross-contamination when, not if, a high-pressure line blows

- Easy to locate a high-pressure leak.

Mixing done by pumping in tank without any moving components

- Fewer moving parts buried in resin and/or catalyst

Hog Bead Guns

- No threads for beads to gall

- Lines machined into the duck bill promote even bead distribution

- Quick assembly / disassembly

Hog Skip Timer

- Ability to change patterns with the touch of a thumbnail showing that pattern

- Continuous monitoring of pressure differential and auto-shutoff if over the adjustable “set point” prevents improper mix

Ultrasonic level sensors in bead tanks

- Data logging and bead levels monitored closely without the use of scales under the tank

Hog Tools

- Placed at the back of the truck so as to reduce exposure to traffic along the side of the vehicle

- Gives your men the spaces and places to stay organized

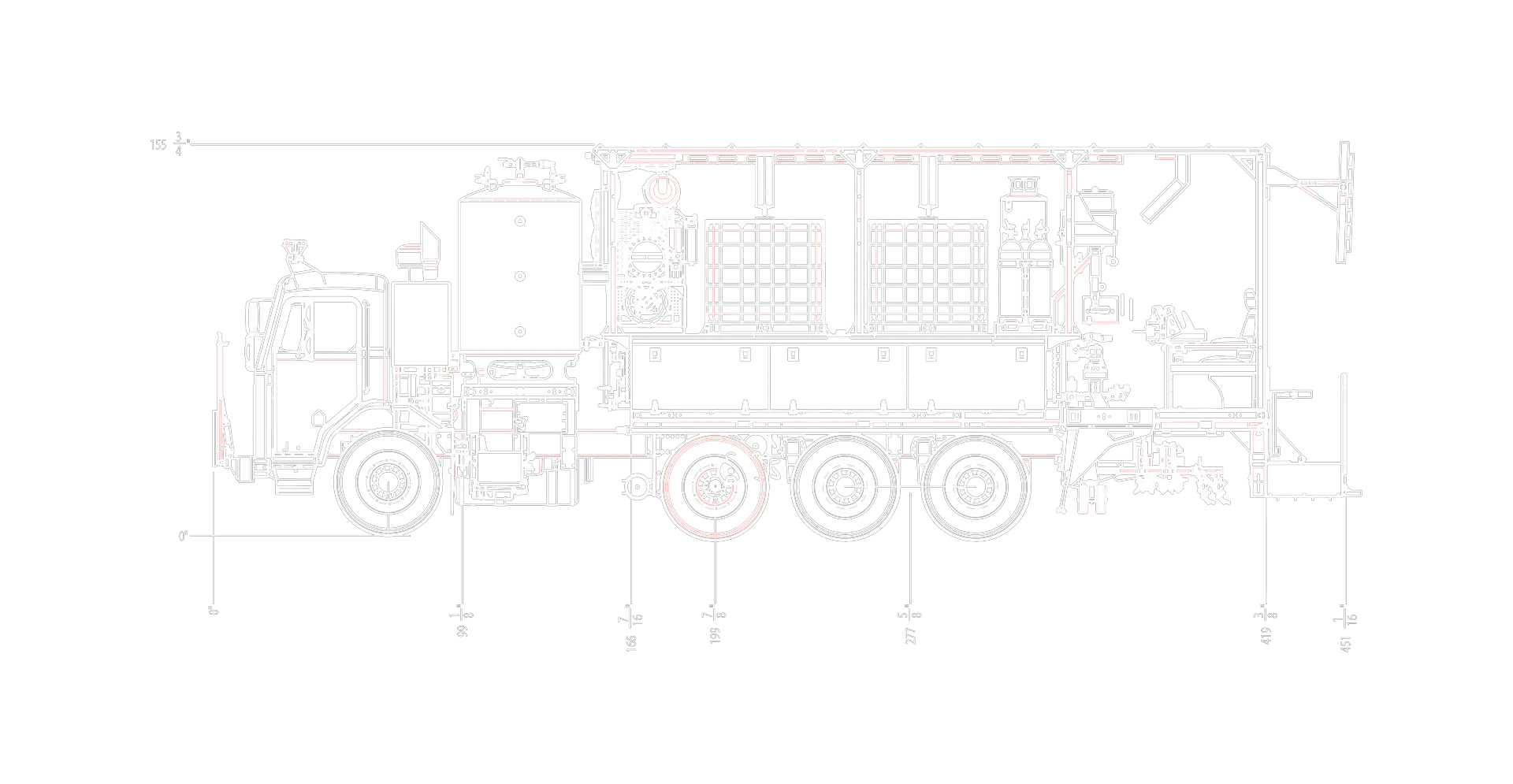

The Epoxy Hog represents a revolutionary way of addressing the complexities of plural component vehicles. You'll find a truck that looks and acts more like a paint truck than what you are used to.

Get the Epoxy Hog specification sheet that you can print and save to your computer for review at any time. A great tool for model comparisons and for comparing the Epoxy Hog to other manufacturer's equipment. Specification sheets contain: